Digital Industries, Motion Control, Machine Tool Systems

Machining threads at the push of a button

Engineers from Emuge Franken and Audi are revolutionizing the way that threads are machined. “Punch-tap” is the name of the new technology where internal M6 threads can be punched approximately 75 percent faster when compared to conventional thread-cutting techniques. As technology partner, Siemens supported the implementation of this new innovative technique using its Mechatronic Support group and generated a user-friendly cycle.

New technology Punch-tap

Punch-tap or helical thread forms – this is the name of the new technology jointly developed by Emuge Franken and Audi where internal M6 threads can be punched in aluminum at lightning speed. The market is very enthusiastic about this innovative technology, which is a combination of punching and forming. This should be of no surprise when considering that threads can be machined 75 percent faster.

This was also clearly demonstrated at the Emuge in-house exhibition at the end of 2015. At the in-house exhibition, visitors had the opportunity to watch a demonstration of the process at regular intervals during the course of the day. Many were clearly impressed, which was reflected in the high level of interest. Dietmar Hechtle, Head of the Technical Department with Emuge Franken, was very happy about this; however, he asked automotive industry customers to be patient.

Background: As Audi had initiated punch-tap technology – and had provided decisive input for its development – those responsible at Audi's head office in Ingolstadt, Germany and Emuge mutually agreed on sector exclusivity with the appropriate blocking periods. Or more precisely: Suppliers to the automotive industry can utilize punch-tap technology starting in January 2017 – and manufacturers from January 2018. Effective immediately, Emuge will offer the technology to all other industry sectors. "We are working flat out so that we can address the number of inquiries and orders that are increasing on almost a daily basis" stated a satisfied Dietmar Hechtle.

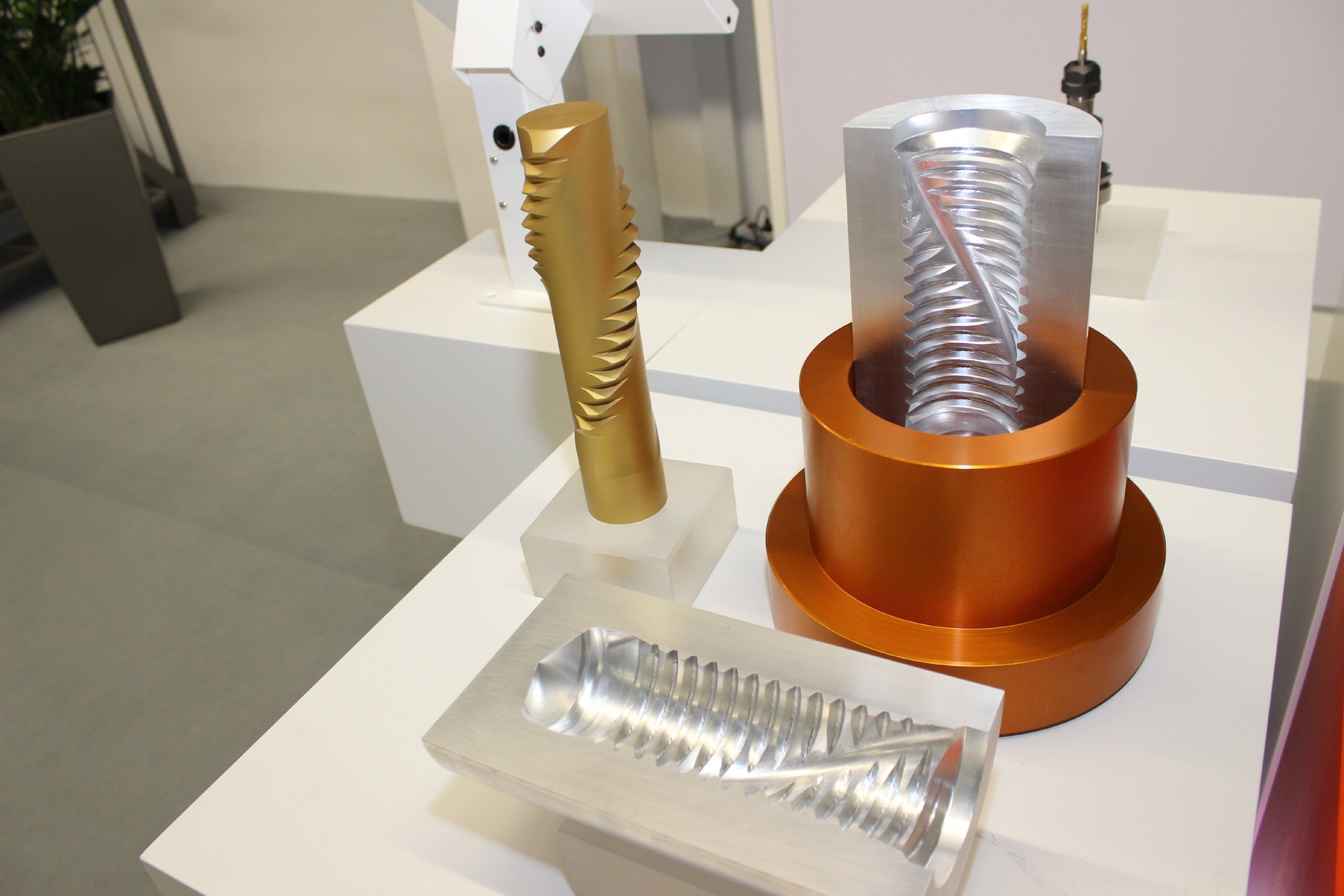

The patented principle: punch first – then form

And this is how it functions: A specially designed punch-tap tool with a twisted series of teeth arranged opposing one another is punched in a fraction of second into a predrilled hole with simultaneous helical motion. This operation creates two spiral grooves. The spindle then rotates through an additional 180 degrees while the axial feed axis is simultaneously withdrawn by half a thread pitch. And it is precisely this motion that forms the thread. The tool can then be quite simply withdrawn helically as the series of teeth are now again in the previously formed grooves. And that completes the operation. Numerous tests were carried out, and it was clearly verified that when compared to other techniques, this innovative process reduces thread machining times by 75 percent.

The geometry and holding forces of the internal threads punched in aluminum for thread size M6 – which is very frequently required – is comparable to conventionally machined threads. Engineer Hechtle stated that the helical groove form is decisive, and: "The thread depth must be at least twice that of the diameter."

A high quality machining center with a stable and high-performance spindle is also a crucial factor. This must provide a very high torque and must also be able to withstand enormous pulling and pushing loads. Emuge Franken engaged Siemens as technology partner early on in the development project to identify just which forces occur at which locations of the machine when punching threads.

Within the scope of mechatronic support, the engineers in the Technology and Application Center (TAC) were able to calculate the relevant forces using a finite element model of the production process. Based on these values, they defined the main data that the machining center must comply with in order to be suitable for the punch-tap technique.

In the meantime, several machining centers that satisfy all criteria have been investigated. If users are interested, but the planned machine has not been evaluated in the relevant detail, then Emuge urgently recommends that it should be thoroughly tested to evaluate its suitability. Both the OEM as well as SIEMENS offers this service.

Mechatronic support and cycle development

In parallel to the mechatronic support they were providing, Siemens engineers developed a cycle with which users can simply integrate the helical thread form into a CNC program. This is available as application for SINUMERIK 840D sl and SINUMERIK 828D of the latest generation V 4.7. Further, it can be subsequently integrated in the previous V4.5 version.

Machine operators and/or programming engineers can simply implement the thread punch cycle using the Sinumerik programGuide G code programming system. Once the coordinates have been defined then only a few menu-prompted keystrokes are required for the necessary twist and reversal points (drilling depth). And it's as simple as that.