Wir führen Werkzeuge zu maximaler Leistung

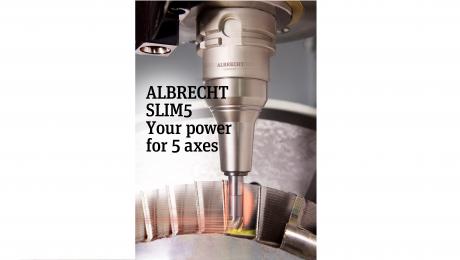

Albrecht offers a new High-Performance-Chuck especially for Volume Cutting

Going max with highest cutting performance

The chip removal rate is an important factor in measuring the productivity of tools and machines of the manufacturing technology. Operators can significantly improve these factors through higher cutting and feed rates - for example with the new precision chuck 'Albrecht Ultra'. Albrecht Präzision GmbH & Co. KG located in Wernau has developed this efficient solution for diameters of 16 to 25 millimetres.

Albrecht has developed the new high-performance chuck especially for volume cutting and machining difficult-to-machine materials. These include components for the aircraft industry. The Ultra Series, which is designed slim from the outside shape, is scheduled for market launch in two sizes for clamping ranges from 16 to 25 millimetres in September 2019. The tools are clamped by a mechanical tensioning gear and a flat coned collet with special coating. This ensures the operator an extraordinarily high clamping force, good damping properties and a high process reliability.

The high balancing quality of G 2.5 to 20,000 rpm protects the machine spindle. If necessary, the chuck can be fine balanced together with the tool. Therefor holes with the dimensions 6xM6 are provided. This not only improves the lifetime of the tool, but also the surfaces during finishing and heavy machining.

Optionally, the operator obtains a peripheral cooling via innovative, exchangeable closing caps with attached holes. This ensures that the coolant is process-reliably supplied to the cutting edge even at higher speeds. Initial test results showed a significantly higher cutting performance and tool life compared to conventional cooling. The closing caps are available with bore angles of 10°, 20° and 30°. Individual adjustments are possible.

Under extreme cutting forces, the Pin-Lock-Collet with radial locking pin in the Weldon clamping surface ensures, that the milling cutters or drills cannot be pulled out or twisted during machining. A first attempt shows how effective the new high-performance chuck is: a chip removal rate MRR of 12 Liters per minutes has been achieved on a machining centre with a power of 100 kilowatts cutting an aluminium component.

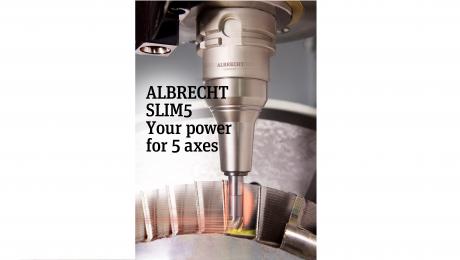

Going max with highest cutting performance

The chip removal rate is an important factor in measuring the productivity of tools and machines of the manufacturing technology. Operators can significantly improve these factors through higher cutting and feed rates - for example with the new precision chuck 'Albrecht Ultra'. Albrecht Präzision GmbH & Co. KG located in Wernau has developed this efficient solution for diameters of 16 to 25 millimetres.

Albrecht has developed the new high-performance chuck especially for volume cutting and machining difficult-to-machine materials. These include components for the aircraft industry. The Ultra Series, which is designed slim from the outside shape, is scheduled for market launch in two sizes for clamping ranges from 16 to 25 millimetres in September 2019. The tools are clamped by a mechanical tensioning gear and a flat coned collet with special coating. This ensures the operator an extraordinarily high clamping force, good damping properties and a high process reliability.

The high balancing quality of G 2.5 to 20,000 rpm protects the machine spindle. If necessary, the chuck can be fine balanced together with the tool. Therefor holes with the dimensions 6xM6 are provided. This not only improves the lifetime of the tool, but also the surfaces during finishing and heavy machining.

Optionally, the operator obtains a peripheral cooling via innovative, exchangeable closing caps with attached holes. This ensures that the coolant is process-reliably supplied to the cutting edge even at higher speeds. Initial test results showed a significantly higher cutting performance and tool life compared to conventional cooling. The closing caps are available with bore angles of 10°, 20° and 30°. Individual adjustments are possible.

Under extreme cutting forces, the Pin-Lock-Collet with radial locking pin in the Weldon clamping surface ensures, that the milling cutters or drills cannot be pulled out or twisted during machining. A first attempt shows how effective the new high-performance chuck is: a chip removal rate MRR of 12 Liters per minutes has been achieved on a machining centre with a power of 100 kilowatts cutting an aluminium component.