Fast and robust for automotive lightweight construction

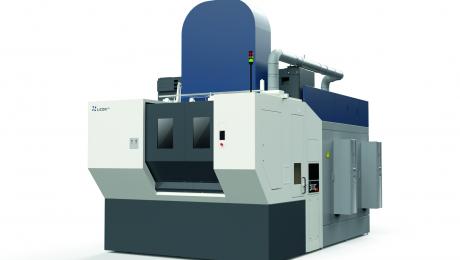

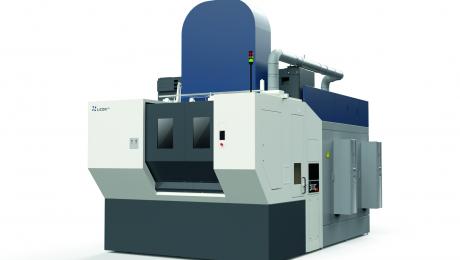

At this year's EMO in Hanover in September, the Laupheim-based machining center manufacturer will present itself with the further development of the LiFLEX I 12126. The new single-spindle machining center shows a unique combination of dynamics and work envelope, used especially for significantly higher processing dimensions like e.g. structural components. The chip-to-chip time is reduced by half. Additional benefits as a cost-cutting tool are provided by Licon Added Value Analysis, or LAVA, to enable predictive maintenance digitally and in real time.

As a further development, the single-spindle LiFLEX I 12126 can process structural components in even larger dimensions than before. The machine works 4- or 5-axis, is particularly fast, dynamically stable and robust. It is designed primarily for the machining of large structural components made of light metal such as aluminum. The tool change time is only 1 second. With rapid traverse speeds in the linear axes up to 150 m / min, high acceleration as well as increase rate of acceleration, the machine is currently one of the most dynamic of this work envelope on the market. Especially short cycle times and thus maximum productivity are the biggest advantages for the customer.

"One application is the processing of engine cradles for passenger cars. Here, it is important that the large component can be positioned freely in the working area and the machining can be carried out at all required areas - if possible without the additional use of angular heads. In order to guarantee the overall performance of the machine, we rely exclusively on the components from our own, LiFLEX modular system, "says Winfried Benz, Managing Director of Licon.

Also as a twin-spindle machining center a class of its own

Based on the LIFLEX machine concept, Licon has developed and established four different platforms and a variety of different machine configurations over the past few years. The machining centers are characterized above all by the free choice of three different loading variants, such as direct loading, double trunnion and pallet changer. For each individual case of application, the optimal solution can be selected from the concept variants.

Twin-spindle machining centers are used where high demands are placed on performance and quantity. Winfried Benz explains: "How powerful our twin-spindle machines are can be seen in the production of goose-neck knuckles on the front axle of an SUV. Such long complex parts are usually made in two setups. We manage this in one clamping and machine two components in one clamping fixture. This is made possible by the large work envelope of our five-axis twin-spindle machining center combined with clever solution expertise in the clamping fixtures."

More production flexibility thanks to independent axes

As a further innovation, Licon offers the i³ technology, which provides independence in three axes for more production flexibility. While the two spindles are often coupled with twin-spindle machining centers, there are already independent Z-axes with the basic configuration. In addition, the i³ technology provides complete decoupling and independence in all three linear axes.

More and more attention is also being paid to Licon Added Value Analysis, in short LAVA. Essentially, this involves the digital processing of a wide range of information on the topics of condition analysis, predictive maintenance and optimization of machining processes. Licon can detect the condition of its machines worldwide by means of suitable sensors. Typical physical parameters such as force, temperature and vibration signals can be individually read out and evaluated.

Convincing overall package - not only for automotive

In times when the industry is discussing digitization, cyber security, artificial intelligence, electromobility and a new understanding of sustainability, Winfried Benz is optimistic about the future: "Vehicles are becoming increasingly easier to build. In this respect, the demand for large cubic structural components is steadily increasing. In the future as well, each car will have four wheels and a steering system and thus needs structural components, regardless of the question of whether combustion engine, electric drive or other alternative type of drive."

In addition to large international customers from the automotive industry, Licon is increasingly serving smaller and medium-sized non-automotive companies. Applications include the series processing of components for lawnmower engines, stainless steel pumps, fittings or door closers. In order to drive growth further, Laupheim has further expanded its service locations in Europe, Asia and America, both in terms of personnel and infrastructure.

About Licon

Licon is a recognized provider of production lines for processing of complex components. Our customers are well-known automotive manufacturers and sub-suppliers in Europe, America and Asia as well as a growing number of companies from other industries. In addition to machine product development of all components which drive performance our expertise extends to their system integration and software development. With headquarters and more than 200 employees in Laupheim, Germany, Licon has subsidiaries in Michigan, USA, and Beijing, China. For more information www.licon.com.

Responsible under press legislation:

Winfried Benz, Managing Director

Licon mt GmbH & Co. KG Im Rißtal 1, 88471 Laupheim

Tel. +49 7392-962-0, Fax +49 7392-962-257 [email protected], www.licon.com

At this year's EMO in Hanover in September, the Laupheim-based machining center manufacturer will present itself with the further development of the LiFLEX I 12126. The new single-spindle machining center shows a unique combination of dynamics and work envelope, used especially for significantly higher processing dimensions like e.g. structural components. The chip-to-chip time is reduced by half. Additional benefits as a cost-cutting tool are provided by Licon Added Value Analysis, or LAVA, to enable predictive maintenance digitally and in real time.

As a further development, the single-spindle LiFLEX I 12126 can process structural components in even larger dimensions than before. The machine works 4- or 5-axis, is particularly fast, dynamically stable and robust. It is designed primarily for the machining of large structural components made of light metal such as aluminum. The tool change time is only 1 second. With rapid traverse speeds in the linear axes up to 150 m / min, high acceleration as well as increase rate of acceleration, the machine is currently one of the most dynamic of this work envelope on the market. Especially short cycle times and thus maximum productivity are the biggest advantages for the customer.

"One application is the processing of engine cradles for passenger cars. Here, it is important that the large component can be positioned freely in the working area and the machining can be carried out at all required areas - if possible without the additional use of angular heads. In order to guarantee the overall performance of the machine, we rely exclusively on the components from our own, LiFLEX modular system, "says Winfried Benz, Managing Director of Licon.

Also as a twin-spindle machining center a class of its own

Based on the LIFLEX machine concept, Licon has developed and established four different platforms and a variety of different machine configurations over the past few years. The machining centers are characterized above all by the free choice of three different loading variants, such as direct loading, double trunnion and pallet changer. For each individual case of application, the optimal solution can be selected from the concept variants.

Twin-spindle machining centers are used where high demands are placed on performance and quantity. Winfried Benz explains: "How powerful our twin-spindle machines are can be seen in the production of goose-neck knuckles on the front axle of an SUV. Such long complex parts are usually made in two setups. We manage this in one clamping and machine two components in one clamping fixture. This is made possible by the large work envelope of our five-axis twin-spindle machining center combined with clever solution expertise in the clamping fixtures."

More production flexibility thanks to independent axes

As a further innovation, Licon offers the i³ technology, which provides independence in three axes for more production flexibility. While the two spindles are often coupled with twin-spindle machining centers, there are already independent Z-axes with the basic configuration. In addition, the i³ technology provides complete decoupling and independence in all three linear axes.

More and more attention is also being paid to Licon Added Value Analysis, in short LAVA. Essentially, this involves the digital processing of a wide range of information on the topics of condition analysis, predictive maintenance and optimization of machining processes. Licon can detect the condition of its machines worldwide by means of suitable sensors. Typical physical parameters such as force, temperature and vibration signals can be individually read out and evaluated.

Convincing overall package - not only for automotive

In times when the industry is discussing digitization, cyber security, artificial intelligence, electromobility and a new understanding of sustainability, Winfried Benz is optimistic about the future: "Vehicles are becoming increasingly easier to build. In this respect, the demand for large cubic structural components is steadily increasing. In the future as well, each car will have four wheels and a steering system and thus needs structural components, regardless of the question of whether combustion engine, electric drive or other alternative type of drive."

In addition to large international customers from the automotive industry, Licon is increasingly serving smaller and medium-sized non-automotive companies. Applications include the series processing of components for lawnmower engines, stainless steel pumps, fittings or door closers. In order to drive growth further, Laupheim has further expanded its service locations in Europe, Asia and America, both in terms of personnel and infrastructure.

About Licon

Licon is a recognized provider of production lines for processing of complex components. Our customers are well-known automotive manufacturers and sub-suppliers in Europe, America and Asia as well as a growing number of companies from other industries. In addition to machine product development of all components which drive performance our expertise extends to their system integration and software development. With headquarters and more than 200 employees in Laupheim, Germany, Licon has subsidiaries in Michigan, USA, and Beijing, China. For more information www.licon.com.

Responsible under press legislation:

Winfried Benz, Managing Director

Licon mt GmbH & Co. KG Im Rißtal 1, 88471 Laupheim

Tel. +49 7392-962-0, Fax +49 7392-962-257 [email protected], www.licon.com