CGTech Announces Programming and Simulation Software

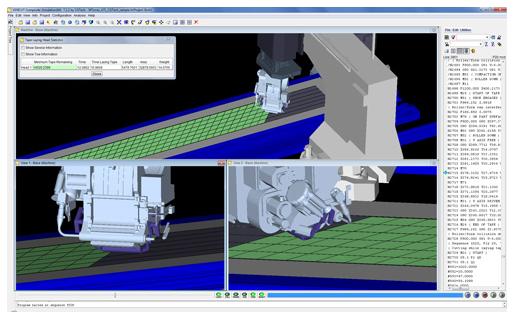

Irvine, California – At the JEC Composites show at the Paris Expo, Porte de Versailles, CGTech demonstrated its new programming and simulation software for Automated Tape Laying (ATL) machines. The new capability complements CGTech’s existing composite software applications for Automated Fiber Placement (AFP).

“We were pleased to work with MTorres to develop programming and simulation software for ATL machines,” said CGTech Product Marketing Manager Bill Hasenjaeger. “CGTech’s manufacturing software expertise, combined with MTorres’ expertise in their ATL equipment and the ATL process has allowed us to create a high-quality set of ATL features in our composites automation software.”

Additionally, visitors had the opportunity to receive a thorough overview of the steps needed to get from a CAD designed composite part to CNC programs that drive automated composite machinery. There was updated information on projects that highlight the implementation and use of machine independent off-line NC programming and simulation software for AFP and ATL machines.

“Manufacturers of AFP and ATL machinery typically supply in-house developed off-line NC programming software that uniquely supports their machine.

Thus companies need to adopt multiple software applications if they implement multiple machine brands,” said CGTech Product Marketing Manager Bill Hasenjaeger. “Because CGTech composites software products are machine-independent, able to support multiple different machine brands from a single software application, companies can select the best factory equipment for the job, while avoiding the added cost and time associated with implementing and supporting multiple software applications for multiple different CNC machines.”

Throughout the show, CGTech demonstrated VERICUT Composite Applications: VERICUT Composite Paths for Engineering (VCPe), VERICUT Composite Programming (VCP) & VERICUT Composite Simulation (VCS).

VCPe gives the user the ability to measure and evaluate the effects of AFP and ATL path trajectory, material steering, surface curvature, course convergence and other process constraints as they would be applied in manufacturing. The software also provides produceability analysis of the fiber angle based on the curvature of the part, and overlap and gaps needed for structural analysis. Tape course geometry can be written to various CAD formats for further evaluation by the user’s existing analysis methods and tools.

VCP reads CATIA V5, STEP, or ACIS surface models. It also reads Fibersim, CATIA V5 or other external ply geometry and information. VCP then adds material to fill the plies according to user-specified manufacturing standards and requirements. Layup paths are linked together to form specific layup sequences and are output as NC programs for the automated layup machine.

VCS reads CAD models and NC programs, either from VCP or other composite layup path-generation applications, and simulates the sequence of NC programs on a virtual machine. Material is applied to the layup form via NC program instructions in a virtual CNC simulation environment. The simulated material applied to the form can be measured and inspected to ensure the NC program follows manufacturing standards and requirements. A report showing simulation results and statistical information can be automatically created.

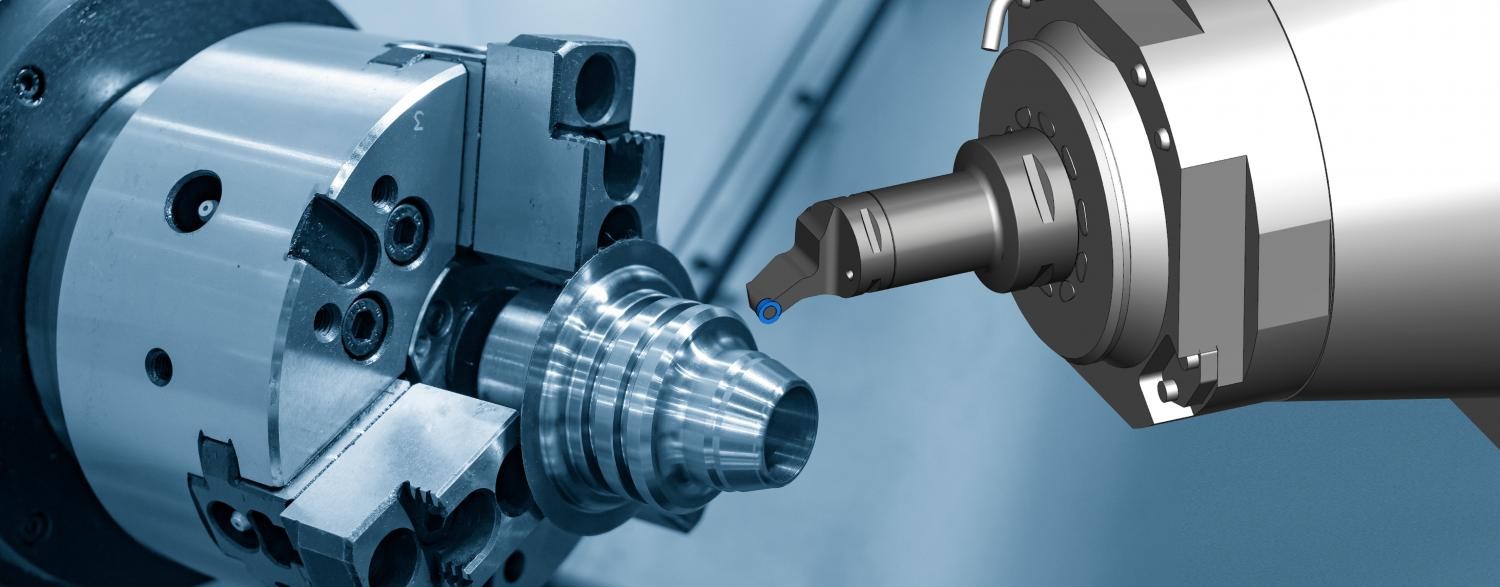

CGTech also exhibited its latest version of VERICUT software. VERICUT is CNC machine simulation, verification and optimization software that enables users to eliminate the process of manually proving-out NC programs. VERICUT simulates all types of CNC machining, including drilling and trimming of composite parts, water jet, riveting, robotics, mill/turn and parallel kinematics. VERICUT runs standalone, but can also be integrated with leading CAM systems.

Responsible for the content of this press release: CGTech Deutschland GmbH